CNC Juya nau'ikan nau'ikan nau'ikan bakin karfe / aluminium mai sassauƙan haɗakarwa don motar

Lanƙwasa muƙamuƙi Couplings

Za'a iya amfani da haɗin gwanon muƙamuƙi mai lanƙwasa a aikace-aikace da yawa kuma suyi aiki azaman haɗakarwa duka.Ƙirar ƙira ta Lanƙwasa jaw tana ba da damar al mafi girman ƙarfin juzu'i a cikin ƙaramin ƙira.Haƙori mai lanƙwasa yana da wurin tuntuɓar mafi girma wanda ke ba shi ƙarfin ƙarfin ƙarfi, kuma yana rage matsa lamba.Zai ɗauki nauyin axial, radial da kuskuren shaft na kusurwa.

Ana samar da cibiyoyi daga abubuwa daban-daban da suka haɗa da: aluminum, launin toka, baƙin ƙarfe, ƙarfe, ƙarfe da ƙarfe, da bakin karfe.Abubuwan abubuwan gizo-gizo suna samuwa a cikin zaɓuɓɓukan durometer daban-daban a cikin Urethane & Hytrel.gizo-gizo na iya yin aiki a ƙarƙashin yanayin zagayowar ayyuka na yau da kullun zuwa zagayawa masu nauyi waɗanda suka haɗa da ɗaukar nauyi kuma suna iya rage girgizar da ke cikin tsarin.

| Samfura | Girman gunki (mm) | RatedTorque (Nm) | MaxTorque (Nm) | Matsakaicin gudun | Diamita na Wuta (mm) | Tsawon (mm) | Haƙurin Haƙuri (mm) |

| Saukewa: HS-TCN-14C | 3 ~ 7 | 0.7 | 1.4 | 45000 | 14 | 22 | +0.6-0 |

| Saukewa: HS-TCN-20C-R | 4 ~ 11 | 1.8 | 3.6 | 31000 | 20 | 30 | + 0.8-0 |

| Saukewa: HS-TCN-30C-R | 6 ~ 16 | 4 | 8 | 21000 | 30 | 35 | + 1.0-0 |

| Saukewa: HS-TCN-40C-R | 8 ~ 28 | 4.9 | 9.8 | 15000 | 40 | 66 | + 1.2-0 |

| Saukewa: HS-TCN-55C-R | 9.5-32 | 17 | 34 | 11000 | 55 | 78 | + 1.4-0 |

| Saukewa: HS-TCN-65C-R | 12.7-38.1 | 46 | 92 | 9000 | 65 | 90 | + 1.5-0 |

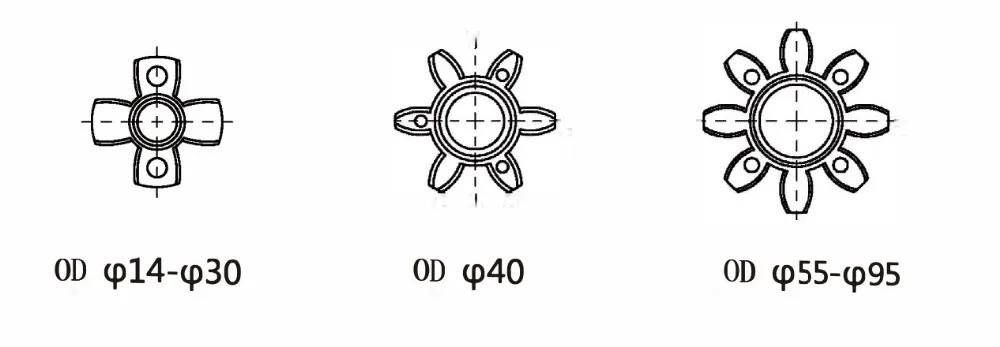

Halayen Spider

Haɗin muƙamuƙi mai lanƙwasa ya haɗa da cibiyoyi na ƙarfe biyu da wani nau'in “gizo-gizo” na elastomeric.Ana samun gizo-gizo a ciki

durometers taurin daban-daban, kowannensu cikin sauƙin gano ta launi.

| Tauri | Launi | Kayan abu | Yanayin Zazzabi | Aikace-aikace |

| 80 Shore A | Blue | Polyurethane | -50 ~+80 .C | Kyakkyawan damping |

| 92 Shore A | Yellow | Polyurethane | -40~+90 .C | Matsakaicin damping, aikace-aikace na gaba ɗaya |

| 98 Shore A | Ja | Polyurethane | -30 ~+90 .C | Babban karfin juyi aikace-aikace |

| 64 Gaba D | Kore | Polyurethane | -50 ~ +120 .C | Ƙarfin ƙarfi mai ƙarfi, zafin jiki mai girma |

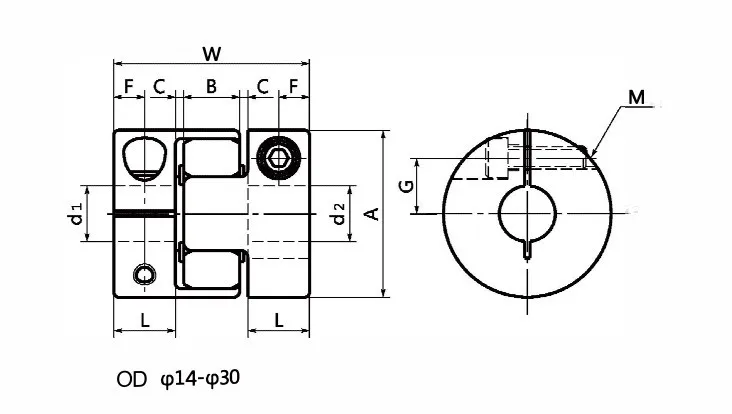

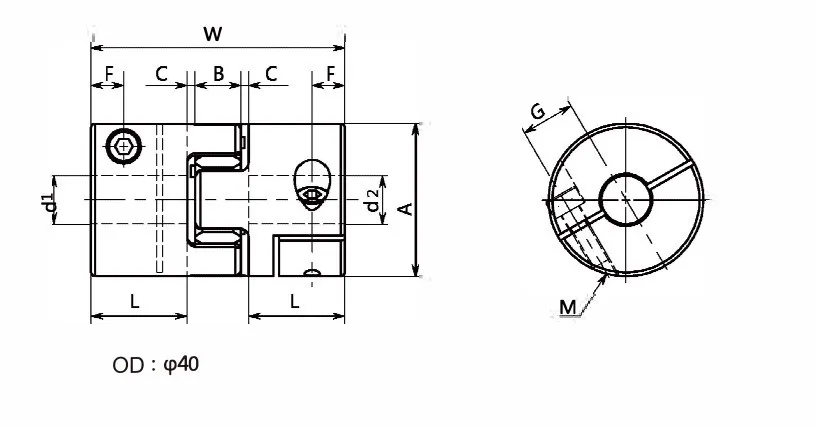

Bayanin auna ma'auni

| A | L | W | B | C | F | G | M |

| 14 | 7 | 22 | 6 | 1 | 3.5 | 4/5 | M2/M1.6 |

| 20 | 10 | 30 | 8 | 1 | 5 | 6.5/7.5 | M2.5/M2 |

| 30 | 11 | 35 | 10 | 1.5 | 8.5 | 10/11 | M4/M3 |

| A | L | W | B | C | F | G | M |

| 40 | 25 | 66 | 12 | 2 | 8.5 | 14/15.75 | M5/M4 |

| A | L | W | B | C | F | G | M |

| 55 | 30 | 78 | 14 | 2 | 10.5 | 20/21 | M6/M5 |

| 60 | 35 | 90 | 15 | 2.5 | 13 | 24/25 | M8/M6 |